Protect up to 8 users per system

Your Fall Protection Is Falling Short

You're spending your time, money, and energy on fall protection that exposes your workers and your business.

No Fall Protection

OSHA requires fall protection for workers at heights. Falls are the leading cause of accidental deaths and injuries. on the job, behind auto accidents.

Unprotected Installer

OSHA requires fall protection for installers of fall protection. Allowance for first man up to not have fall protection is only allowed for inspectors.

Fake Fall Protection

Is your fall protection so difficult your workers won't use it properly? They disconnect from their lifeline or create an extra long lifeline that won't protect them.

Nails and Screws Damage Roofs

Roof penetrations increase the chances of leaky roofs and damage to your customer's property exposing, your business to costly claims.

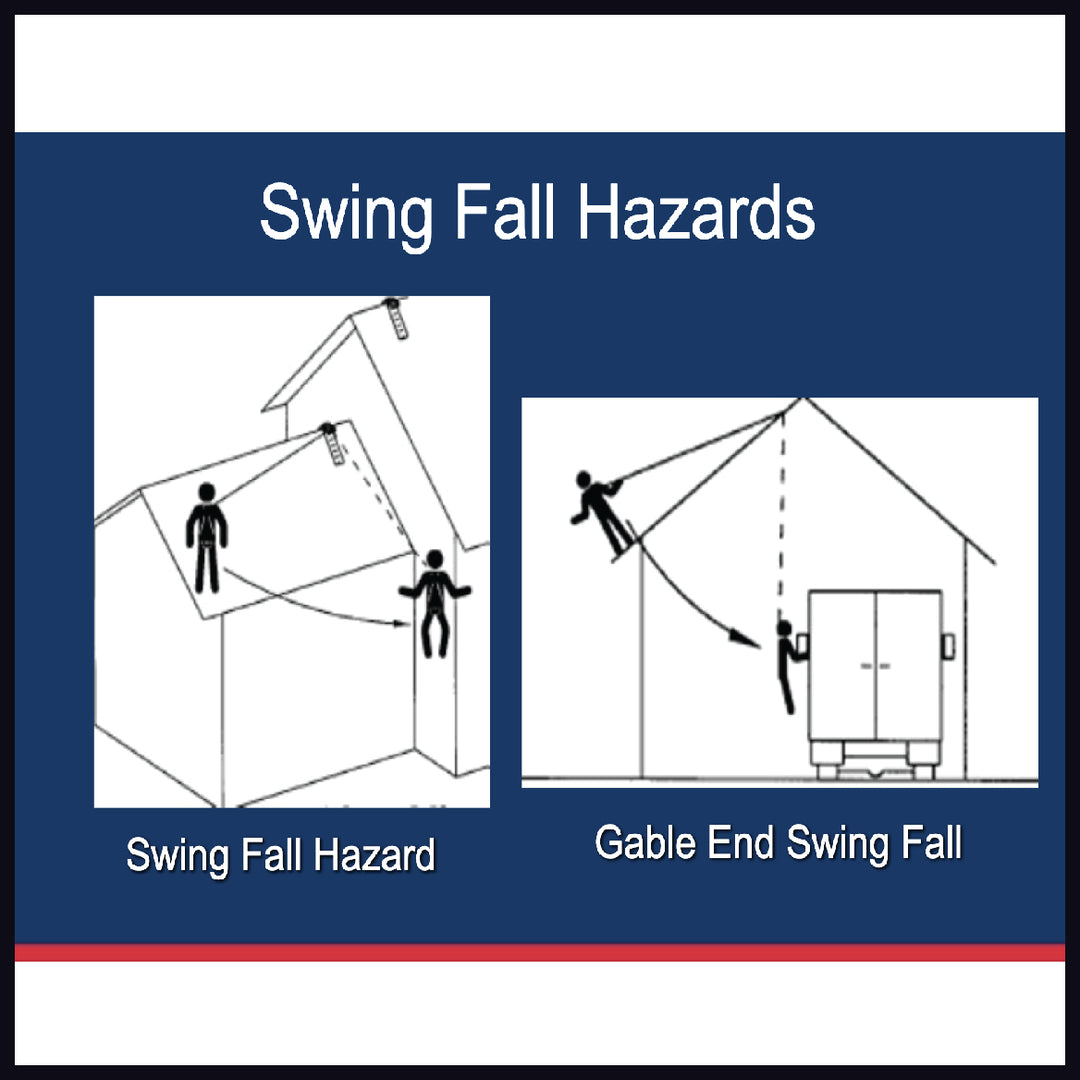

Swing Falls from single point anchors

Swing falls are often a result from single point anchors that allow swing falls hazards that are so bad that the user can strike the ground.

Multi-Employer Citation Policy

With OSHA's Multi-Employer Citation Policy, subcontractors, general contractors and some property owners are subject to fines and lawsuits up to and over a million dollars.

The Ballantyne Gear Solution

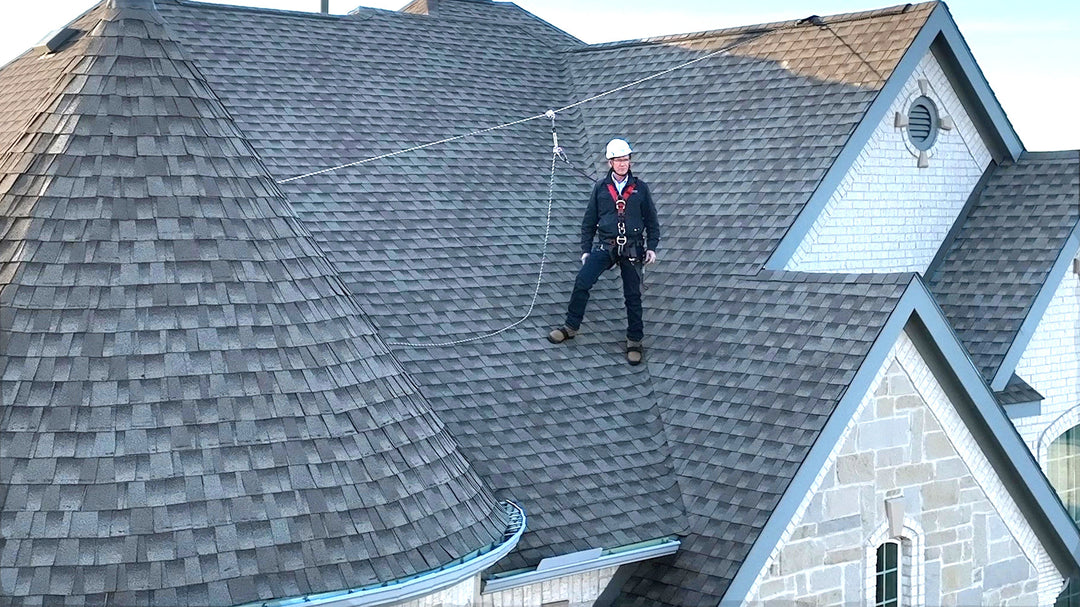

work system with fall protection

Swing falls avoided

The Ballantyne Gear Eveook system is easily installed in less than 15 minutes. The horizontal anchor line with adjustable lifelines can be used to avoid swing falls and keep workers in travel restraint.

Installer is Protected

Workers can easily install their fall protection without getting on the roof, protecting them from fall hazards resulting in injuries and death, and protecting your business from devastating fines and lawsuits.

No Roof Penetrations

Customers do not want holes in their roof! Protect their property and they will reward you with loyalty and referrals. Eveooks only weigh 22 pounds.

Protection on Ladder

In the image you can see a worker carrying a 65" x 39" solar panel while attached to a lifeline that will restrict a free fall to not more than two feet.

Ground to roof Fall protection

Worker is protected from the ladder to the roof, one of the most dangerous places to be. Reducing accidents and injuries keep your people safe, productivity high, and costs down.

Certified engineered system

The Ballantyne Gear, Inc. Eveook System is certified to the ANSI Z359.6-16 and CSA Z259.16-15 standard as an engineered fall protection system for residential style sloped roofs on residential and commercial buildings for up to 8 users per system, when used as specified in the technical manual.

Testing performed at an independent ISO 17025 accredited laboratory. Also, meets US OSHA CFR 1910.140 Appendix D, CFR 1926.502 Appendix C, and ANSI Z359.18.

Testimonials

"The introduction of the Eveook fall restraint and arrest system has revolutionized the way we approach our solar rooftop installations. It is an invaluable asset that not only safeguards our workers, but also contributes to a more efficient and successful project."

-Jaime Hernandez, Safety Engineer and Jasept Barriere, Asst. Safety Engineer

City of Los Angeles - Department of Water and Power

City of Los Angeles Department of Water and Power Los Angeles, CA

Los Angeles, CA

"As I got the opportunity to experience and train with the Ballantyne Gear System, I realized that this safety equipment is a game changer. I had the pleasure of meeting Mr. Ballantyne and could see the passion he has for safety. This product also proves to be very beneficial as it does not require any mounting or drilling into the customer’s home, reducing leak liability concerns."

Sunnova Energy Houston, TX

Houston, TX

"Our team participated in a two-day training with Ballantyne Gear and left extremely confident on how to utilize the fall protection system. Their team is very knowledgeable and experienced with assisting on specific roof applications. Training was hands-on and paced appropriately. While the system is extremely user friendly, the training gave our team insight on utilization. I cannot recommend the system and training highly enough!"

Adam Sartin, President Christmas Décor by My Ground Crew

Christmas Decor Jonesboro, AR

Jonesboro, AR

"Ballantyne Gear is a great, well designed, innovative product. Our production manager and two of our foreman flew down to Dallas last week and went through their training and were thoroughly impressed. They came away with how to safely, correctly, effectively and efficiently use their product. They now feel ready and confident to use Ballantyne Gear on our clients' roofs with 100% fall protection. I feel good knowing my staff will be safe and more productive and despite the expense we ordered another kit today. It is well worth the money spent to have the peace of mind, that they are safe today."

Naylor Landscape Management Kalamazoo, MI

Kalamazoo, MI

"The rodent guys with my pest control company are on roofs everyday doing what they do. Eveook is the perfect system to have my guys do the job they need to do with a safe and easy to use fall protection system."

Jeremy Logsdon, Owner

Preventive Pest Control Houston East Houston, TX

Houston, TX

"Flent has put an amazing amount of effort into the safety factors associated with the Eveook components, particularly the casting. I work with cast aircraft structure components that do not have safety factors as high!"

Randy Oehrlein, Chief Engineer

Carley Foundry Blaine, MN

Blaine, MN

call now

Call now and discuss your fall protection needs with one of our Ballantyne Gear fall protection specialists. We will help you create a system for your needs.

custom quote

After your consultation we will prepare your personalized quote and send it via email.

choose training

We offer training at our facilities in Texas, or we can train at a location of your choosing.

What Our Customers Say

Hear from the people who matter most — our customers. Read their real experiences and discover why they trust and love our services.

I’m Matthew Wheelwright, writing a letter of recommendation for the Ballantyne Gear Eveook Fall Protection System.

I received a PhD in Metropolitan Planning, Policy, and Design with emphasis in Urban Design and Development from the University of Utah in 2020. I received a BS degree in Construction Management from Brigham Young University (“BYU”) in 2000. I have also received an MBA degree from BYU in 2013.

I am currently an Assistant Teaching Professor at Brigham Young University (“BYU”) in the Department of Civil and Construction Engineering. I have been a professor at BYU since 2021. Prior to being a professor, I was a Project Manager and Director at Standard Pacific Homes from 2000-2008; a consultant for Guinn Construction from 2008- 2009; and a General Manager with Millhaven Homes from 2013-2014. In these positions, I have overseen the construction and management of hundreds of homes and the thousands of workers involved with such endeavors.

Having experience in construction, including residential construction, I am familiar with safety concerns related to workers working on elevated structures, including sloped roof surfaces. I am also familiar with the various systems and methods commercially available to help protect workers from falls, including non-penetrating systems that do not cause damage to the roof or building as part of installation. One such non-penetrating, sloped roof system is Ballantyne Gear’s Eveook Fall Protection System commercially available through Ballantyne Gear at https://www.ballantynegear.com/collections/product-list (“Eveook System”).

I first learned about the Eveook System at the National Association of Homebuilders (NAHB) International Builders Show (IBS) in 2024, where I saw demonstrations and videos of the system. I purchased a partial version of the Eveook System to use in a Construction Safety Class I teach at BYU (CFM 345).

I was particularly impressed by two primary benefits of the Eveook System over other non-penetrating, sloped roof fall protection systems of which I am aware.

One of these benefits is the ability to install the Eveook System from positions on the ground and/or on a ladder. There is no need for an installer to physically

climb onto the sloped roof, unprotected from a fall, to install the Eveook System. There are other systems that require an installer to be on the roof, and particularly at or near the roof peak to connect components of the system together as part of installation, making the installer vulnerable to a fall. The Eveook System uses a line thrower to position a single anchor line over the sloped roof to connect the two eave anchors together without requiring the installer to physically climb on the roof unprotected.

There has been a need in the industry for many years for a non-penetrating fall protection system for use on sloped roofs that allows installation without the user having to climb on the roof. Prior to the introduction of the Eveook System in 2018, I am not aware of any non-penetrating fall protection system for use on sloped roofs that could be installed without the user having to climb on the roof – climbing on the roof was standard for installation of such systems.

A second benefit of the Eveook System is providing two points of connection that both allow for sliding and anchoring. This is illustrated in the blue and yellow circles added to the drawing below, which is reproduced from the Technical Manual for the Eveook System (available under the Technical Tab at https://www.ballantynegear.com).

First, the user’s personal lanyard/harness is connected to the lifeline using a rope grab or Goblin. This connection point is shown in the blue circle. This type of connection to the lifeline has been used in other systems prior to the Eveook System.

Second, the user’s lifeline is connected to the anchor line, using a rope grab or Goblin. This connection, which is shown in the yellow circle, is new and unique in the Eveook System.

The use of a rope grab or Goblin for these connections allows each connecting device to freely slide along the line to which it is connected (the anchor line or the lifeline) in one direction but do not allow free sliding in the opposite direction unless the rope grab or Goblin is actuated by the user to allow sliding in that direction. By not allowing free sliding in the opposite direction, the rope grab or Goblin allows the user to anchor to a selected position on both the anchor line and the lifeline. Other systems that I am aware of may allow similar sliding and anchoring on the lifeline (the blue circle), but not on the anchor line (the yellow circle) and on the lifeline (the blue circle).

Alternatively, from paragraph 9, the user’s personal lanyard/harness can be connected to the lifeline using a fall arrester that will move freely up and down the line, when hands free fall protection is required, such as when tearing off shingles from a roof.

There has been a need in the industry for many years for a non-penetrating fall protection system for use on sloped roofs that allows a user to safely access greater areas of the roof. Prior to the introduction of the Eveook System in 2018, I am not aware of any non-penetrating fall protection system for use on sloped roofs that included two connection points that both allow for sliding and anchoring, one being for connecting the user to the lifeline and the other being for connecting the lifeline to the anchor line. For other systems, the connection of the lifeline to the anchor line is either (1) freely sliding in both directions (no anchor point at all), which presents a risk of falling off the roof completely) or (2) is a fixed anchor point (usually at the roof peak), which limits the user’s ability to safely access all points of the roof needing work or requires the user to lengthen the distance between the lifeline connection and the anchor line to reach those areas, which can also result in a fall.

Another note is that the Eveook System is simple. One of the greatest difficulties in our industry to compelling front line workers to follow through with the proper use of safety devices is that they are complex and difficult to use. The Eveook System is wonderfully straight forward.

When I first saw the Eveook system, I was instantly enamored and saw the great potential. That is why I purchased a set for the classroom. I needed my students to understand the value and critical importance of using the right tools for the right job.

Respectfully,

Matthew Wheelwright

Date: 4/22/2025

I'm Jaime Hernandez, writing a letter of recommendation for the Ballantyne Gear Eveook Fall Protection System.

1. I received a Bachelor of Science degree in Safety from California State University Los Angeles in June 1996.

2. I am currently a Safety Engineer with the Los Angeles Department of Water and Power ("LADWP") and have held this position since October 2011. Prior to this position, I was a Safety Engineer Associate for 5 years.

3. I am familiar with Ballantyne Gear's Eveook Fall Protection System, which can be used on sloped roofs and is currently commercially available through Ballantyne Gear at https://www.ballantynegear.com/collections/product-list ("Eveook System"). I am also familiar with methods of using the Eveook System through demonstrations and my work with LADWP.

4. As part of my duties for LADWP, I oversee solar rooftop installations. LADWP is currently using the Eveook System for these installations. Prior to that time, LADWP used conventional fall protection that included ropes and rope grabs. The challenge of using conventional fall protection was identifying suitable anchor points to connect to and be able to support the weight and forces from a fall. We would use nearby trees or cars as anchor points. There are systems that include anchors that can be attached to the roof or building structure using nails or screws, but those cause damage that also requires repair. At LADWP, we did not want to use those systems because of that damage. Before learning of the Eveook System, we could not find a suitable non- penetrating fall protection system to use that could anchor to the building structure without damage and that did not require locating an external anchor near the job site. In my opinion, the Eveook System provides benefits that are not available in other fall protection systems.

5. One of these benefits is the ability to install the Eveook System from positions on the ground and/or on a ladder. There is no need for an installer to physically climb onto the sloped roof, unprotected from a fall, to install the Eveook System. There are other systems that require an installer to be on the roof, and particularly at or near the roof peak to connect components of the system together as part of installation, making the installer vulnerable to a fall. The Eveook System uses a line thrower to position a single anchor line over the sloped roof to connect to two eave anchors together without requiring the installer to physically climb on the roof unprotected.

6.There has been a need in the industry for many years for a non-penetrating fall protection system for use on sloped roofs that allows installation without the user having to climb on the roof. Prior to the introduction of the Eveook System in 2018, I am not aware of any non-penetrating fall protection system for use on sloped roofs that could be installed without the user having to climb on the roof, which is standard for installation of such systems.

7. A second benefit of the Eveook System is providing two points of connection that both allow for sliding and anchoring. This is illustrated in the blue and yellow circles added to the drawing below, which is reproduced from the Technical Manual for the Eveook System (available under the Technical Tab at https://www.ballantynegear.com).

8. First, the user's personal lanyard/harness is connected to the lifeline using a rope grab or Goblin. This connection point is shown in the blue circle. This type of connection to the lifeline has been used in other systems prior to the Eveook System.

9. What is new and unique in the Eveook System is the second connection point that connects to the user's lifeline to the anchor line, which is shown in the yellow circle. Both connections use a rope grab or a Goblin. The use of a rope grab or Goblin allows each connecting device to freely slide along the line to which it is connected (the anchor line or the lifeline) in one direction but to not allow free sliding in the opposite direction unless the rope grab or Goblin is actuated by the user to allow sliding in that direction. By not allowing free sliding in the opposite direction, the rope grab or Goblin allows the user to anchor to a selected position on both the anchor line and the lifeline. Other systems that I am aware of may allow similar sliding and anchoring on the lifeline (the blue circle), but not on the anchor line (the yellow circle) and the lifeline (the blue circle).

10. There has been a need in the industry for many years for a non-penetrating fall protection system for use on sloped roofs that allows a user to safely access greater areas of the roof. Prior to the introduction of the Eveook System in 2018, I am not aware of any non-penetrating fall protection system for use on sloped roofs that included two connection points that both allow for sliding and anchoring, one being for connecting the user to the lifeline and the other being for connecting the lifeline to the anchor line. For other systems, the connection of the lifeline to the anchor line is either (1) freely sliding in both directions (no anchor point at all), which presents a risk of falling off the roof completely) or (2) is a fixed anchor point (usually at the roof peak), which limits the user's ability to safely access all points of the roof needing work or requires the user to lengthen the distance between the lifeline connection and the anchor line to reach those areas, which can also result in a fall.

11. I believe the combination of the line thrower for installation without having to be on the roof and the two connection points for both anchoring and sliding are new and unique to the Eveook System and have addressed the need for improved safety in the industry.

12. I am not aware of any other non-penetrating fall protection system for use on sloped roofs that provides these benefits of the Eveook System. The conventional fall protection system involving ropes tied to nearby trees, cars, or other structures we used at LADWP prior to adopting the Eveook System did not provide these benefits.

13. The introduction of the Eveook System has revolutionized the way LADWP approaches our solar rooftop installations. It is an invaluable asset that not only safeguards our workers but also contributes to a more efficient and successful project. In the past, it took extra time to find a suitable nearby anchor point, such as a tree or car, and to tie off to that anchor point. With the Eveook System, we can anchor directly to the eaves of the roof, which makes installation faster and easier. Installation of the prior system would take 1-2 hours but, for the same roof, the Eveook System would take 15- 30 minutes. That time savings allows us to complete more installations than we could previously and our workers are safer than they were when using ropes tied to trees or cars.

Respectfully,

Jaime Hernandez

Matthew Wheelwright

Date: 4/24/2025

I’m Matthew Murphy, writing a letter of recommendation for the Ballantyne Gear Eveook Fall Protection System.

1- I am the owner of SEE Inc. (“SEE”), a consulting firm specializing in workplace safety. SEE was founded in 1992 and has been serving the Maryland, Virginia, and DC area ever since. I started here in 1998 and by 2003 I had purchased the company and have been running SEE ever since. I have traveled the entire country training in various subjects including Fall Protection in all 50 states. SEE provides safety solutions and education to our clients, including job-site inspections, safety audits, and OSHA-compliant courses. We also recommend products and methods to improve safety for our clients’ employees and contractors. Some of the courses we offer include Fall Protection; Fall Protection ABC’s; Fall Protection User Training; Fall Protection Awareness; Fall Protection Equipment Inspection and Maintenance; Fall Protection Competent Person; Fall Protection Rescue Awareness; and How to Prevent Falls in Residential Construction.

2- I am very familiar with safety concerns related to working on elevated structures, including sloped roofs common in residential construction. I also know the various systems and methods commercially available to protect workers from falls, including non-penetrating systems that do not damage the roof or building during installation. One such non-penetrating sloped roof system is Ballantyne Gear’s Eveook Fall Protection System, available at https://www.ballantynegear.com/collections/product-list (“Eveook System”). I believe the Eveook System offers two main benefits over other non-penetrating, sloped roof fall protection systems I’ve seen.

3- One benefit is that the Eveook System can be installed from the ground or a ladder. The installer does not need to climb onto the sloped roof unprotected to install the system. Other systems require the installer to be on the roof, often near the peak, which creates a fall hazard. The Eveook System uses a line thrower to position a single anchor line over the roof to connect two eave anchors, eliminating the need to physically get on the roof unprotected.

4- The industry has long needed a non-penetrating fall protection system for sloped roofs that can be installed without climbing onto the roof. Before the Eveook System launched in 2018, I was not aware of any such system where installation didn’t require someone to climb on the roof — the “1st person up” was always necessary.

5- A second benefit of the Eveook System is that it provides two connection points, both allowing for sliding and anchoring. This is shown in the blue and yellow circles from the Technical Manual for the Eveook System (available under the Technical Tab at https://www.ballantynegear.com).

6- First, the user’s lanyard/harness is connected to the lifeline using a rope grab or Goblin. This connection point is shown in the blue circle. This method has been used in previous systems.

7- What’s unique about the Eveook System is the second connection point—shown in the yellow circle—that connects the lifeline to the anchor line. Both points use a rope grab or Goblin, allowing each connector to freely slide in one direction along its line, but not in the other direction unless manually actuated. This feature anchors the user at a chosen position on both the lifeline and the anchor line. Other systems I’ve seen may allow sliding and anchoring on the lifeline (blue circle), but not on the anchor line (yellow circle) as well.

8- Alternatively, the user’s lanyard/harness can be attached to the lifeline using a fall arrester that moves freely up and down, allowing hands-free protection—useful when removing shingles.

9- The industry has also needed a non-penetrating fall protection system for sloped roofs that lets users safely access larger areas. Before the Eveook System debuted in 2018, I wasn’t aware of any system with two connection points that both allow for sliding and anchoring—one from the user to the lifeline, and one from the lifeline to the anchor line. Other systems either (1) allow the lifeline to freely slide in both directions (offering no anchor point, and increasing fall risk) or (2) have a fixed anchor point (usually at the roof peak), limiting safe access and potentially requiring users to extend their reach in unsafe ways.

10- As a Judge for the National Association of Home Builders Safety Awards for over a decade, I can say that when the Eveook System was submitted for the Job-Site Safety Institute Innovative Safety Idea of the Year award in 2023, it clearly stood out. The absence of a “1st person up” requirement—meaning no one was in a fall hazard during installation—was a key reason. The judges, including myself, unanimously voted to award Ballantyne Gear’s Eveook System the Innovative Safety Idea of the Year.

Respectfully,

Matt Murphy

Date: 4/23/2025

I’m Jesse Mattner, writing a letter of recommendation for the Ballantyne Gear Eveook Fall Protection System.

1- I received a Bachelors Degree in Political Science and Journalism in from University of Wisconsin-Madison in 2003. Please list any other degrees or certifications you have, along with the school/issuing entity, and year].

2- I am currently the Managing Director at C.A.M.P. USA Inc. (“C.A.M.P.”) and have held this position since 2010.

3- C.A.M.P. is a manufacturer and developer of equipment, such as carabiners, rope tools, and harnesses, for use in climbing related sports and working at heights. C.A.M.P. is also heavily invested in Research & Development of these products and finding ways to provide more safety protections to climbers and workers working on elevated structures. Through my work with C.A.M.P., I am very familiar with these types of products, as well as safety concerns related to workers working on elevated structures, including sloped roof surfaces. I am also familiar with the various systems and methods commercially available to help protect workers from falls, including non-penetrating systems that do not cause damage to the roof or building as part of installation. One such non-penetrating, sloped roof system is Ballantyne Gear’s Eveook Fall Protection System commercially available through Ballantyne Gear at https://www.ballantynegear.com/collections/product-list (“Eveook System”).

4- I believe the Eveook System provides two primary benefits over other non-penetrating, sloped roof fall protection systems of which I am aware.

5- One of these benefits is the ability to install the Eveook System from positions on the ground and/or on a ladder. There is no need for an installer to physically climb onto the sloped roof, unprotected from a fall, to install the Eveook System. There are other systems that require an installer to be on the roof, and particularly at or near the roof peak to connect components of the system together as part of installation, making the installer vulnerable to a fall. The Eveook System uses a line thrower to position a single anchor line over the sloped roof to connect to two eave anchors together without requiring the installer to physically climb on the roof unprotected.

6- There has been a need in the industry for many years for a non-penetrating fall protection system for use on sloped roofs that allows installation without the user having to climb on the roof. Prior to the introduction of the Eveook System in 2018, I am not aware of any non-penetrating fall protection system for attaching to sloped roofs that could be installed without the user having to climb on the roof – climbing on the roof was standard for installation of such systems.

7- A second benefit of the Eveook System is providing two points of connection that preferably use certified rope access back up devices, such as a Goblin, to both allow for sliding and anchoring. Although a Goblin is preferred, a simple rope grab that meets the standards of an OSHA compliant fall arrester may also be used to provide both sliding and anchoring. This is illustrated in the blue and yellow circles added to the drawing below, which is reproduced from the Technical Manual for the Eveook System (available under the Technical Tab at https://www.ballantynegear.com).

8- First, the user’s personal lanyard/harness is connected to the lifeline using a certified rope access backup device like the Goblin. The Goblin is one of C.A.M.P.’s products. This connection point is shown in the blue circle. This type of connection to the lifeline has been used in other systems prior to the Eveook System.

9- Alternatively, from paragraph 9, the user’s personal lanyard/harness can be connected to the lifeline using a fall arrester that will move freely up and down the line, when hands free fall protection is required, such as when tearing off shingles from a roof.

10- What is new and unique in the Eveook System is the second connection point that connects to the user’s lifeline to the anchor line, which is shown in the yellow circle. Both connections use a certified rope access backup device like the Goblin that is designed to withstand and is certified for the dynamic loads generated by a falling worker. The use of a preferred certified rope access backup device like the Goblin allows each connecting device to freely slide along the line to which it is connected (the anchor line or the lifeline) in one direction but to not allow free sliding in the opposite direction unless the certified rope access backup device is actuated by the user to allow sliding in that direction. By not allowing free sliding in the opposite direction, the certified rope access backup device allows the user to anchor to a selected position on both the anchor line and the lifeline with a system that is designed to withstand and is certified for the dynamic loads generated by a falling worker. Other systems that I am aware of may allow similar sliding and anchoring on the lifeline (the blue circle), but not on the anchor line (the yellow circle) and the lifeline (the blue circle). The preferred use of a certifed rope access backup device like the Goblin, or even a rope grab, on two different lines is something that would not have occurred to me to do as an improvement in safety, but has proven to be a great innovation in the Eveook System and an advancement in roof worker safety.

11- There has been a need in the industry for many years for a non-penetrating fall protection system for use on sloped roofs that allows a user to safely access greater areas of the roof. Prior to the introduction of the Eveook System in 2018, I am not aware of any non-penetrating fall protection system for attaching to sloped roofs that included two connection points that both allow for sliding and anchoring, one being for connecting the user to the lifeline and the other being for connecting the lifeline to the anchor line. For other systems, the connection of the lifeline to the anchor line is either (1) freely sliding in both directions (no anchor point at all), which presents a risk of falling off the roof completely) or (2) is a fixed anchor point (usually at the roof peak), which limits the user’s ability to safely access all points of the roof needing work or requires the user to lengthen the distance between the lifeline connection and the anchor line to reach those areas, which can also result in a fall.

12- I understand that, in hindsight, the benefits of the Eveook System may be achieved by relatively simple devices and methods of using those devices. However, despite being involved in product development at C.A.M.P., having extensive knowledge of rope related safety equipment (including C.A.M.P.’s Goblin), being aware of the long felt need in the industry to address these issues, and having a desire to improve upon the safety of such systems, it would not have occurred to me to use the combination of components used in the Eveook. I believe the combination of the line thrower for installation without having to be on the roof and the two connection points for both anchoring and sliding are new and unique to the Eveook System and have addressed the need for improved safety in the industry.

Respectfully,

Matt Murphy

Date: 03/13/2025

I’m Greg Small, the Professional Engineer retained to oversee and conduct quality control, testing analysis, and certifications on the Ballantyne Gear fall‑protection system, the Eveook System. I am writing this letter of recommendation for the Ballantyne Gear Eveook Fall Protection System.

1. I received a Civil Engineering degree in 1979 from The University of British Columbia in Vancouver, BC, Canada, and a Master’s Degree in Structural Engineering from the University of Alberta in Edmonton, Alberta, Canada.

2. I am a licensed Professional Engineer in Canada (AB) and the United States (AZ).

3. I chaired the development of the CSA (Canadian Standards Association) Z259.16 standard in Canada, which was adopted in the United States as ANSI (American National Standards Institute) Z359.6 for the design of Active Fall Protection Systems.

4. I have trained more than 1,000 engineers in the engineering techniques I developed for the analysis of Active Fall Protection Systems.

5. I am the founder of Elevated Insight and founded High Engineering Corp in 2005, which was sold to Parsons Engineering in 2016. Prior to that, I was employed as Vice President of Engineering at Gravitec Systems from 1996 to 2003. From 1979 to 1996 I worked as a Railway Bridge Engineer where I first was required to develop engineering techniques to protect bridge workers from falls.

6. My Curriculum Vitae indicating additional information on my background and professional qualifications and experience is available on request.

7. I first met Flent Ballantyne, the founder of Ballantyne Gear, at the ANSI Z359 Fall Protection meeting in 2011, where he attended the Z359.18 standard on anchorage connectors I was chairing at that time.

8. Ballantyne Gear retained me as a Professional Engineer to provide engineering support for further enhancements to the Ballantyne Gear fall‑protection system, to oversee quality control, testing, and certifications. I will refer to the Ballantyne Gear fall‑protection system, as it was when I first started working with them, as the “Original System” and the current system as the “Current System.”

9. Two of the safety enhancements we were seeking included protecting the installer and avoiding dangerous swing falls. With the Original System, the installer was required to be on the roof, without fall protection. At that time, being on the roof unprotected during installation was standard practice and not prohibited by OSHA. Ballantyne Gear and I were determined to develop methods to protect persons installing and using the system from both risks.

10. Classic anchorage systems for roof fall protection generally involve one or more fixed anchorage locations to be mounted on the roof. Roofing activities often require workers to move over most of the roof surface. Often, they are not adjacent to the anchorages that their personal fall protection must be connected to. Their level of safety decreases as they get further from their anchorages. If they fall, gravity always pulls and/or swings them to the lowest possible elevation, which will be controlled by the length of their connection to the anchorage and the location of the anchorage. When they have long anchor lines, these systems often allow serious injuries from impacting the ground or swinging into obstructions. The photograph in Figure 1, below, illustrates a classic fall‑protection scenario for a residential roofer who is working a long distance from his anchorage, who is not adjusting the line connecting him to his anchorage. If he falls, he has so much rope that he will impact the ground and/or swing into something at a speed that could cause serious injuries.

Classic fall protection is ineffective when the worker is too far from the anchorage.

The worker needs to move side to side on this roof. Even if properly trained and supervised, he still needs a lot more anchorages to do this work safely. This will increase the cost of anchorages, the number of damaging penetrations into the roof structure, and will slow the work down as the worker needs to transfer to different anchorages as he moves along the roof.

The Current Eveook System, shown below, does not require any penetrations of the roof and causes only minimal cosmetic damage to the roof in the very rare event that a fall occurs. It allows the anchor point (the rope grab/fall arrester that attaches the lifeline to the Eveook anchor line that is crossing the roof) to lock onto the anchor line anywhere between the two Eveooks. The anchor line of the Eveook System can be installed in any direction across the roof, provided the tensioned anchor line stays perpendicular to the edges of the roof. Figures 2 and 3 show photographs of the Current System.

The length of the worker’s lifeline, connecting him to the Eveook anchor line, gives a larger protected working area. The length of the lifeline can be restricted such that the user can reach, but not fall, from the roof edge.

The user can easily slide and relock his connection of the lifeline to the anchor line, such that the user can often maintain travel restraint for the full length of a building without detaching his or her lifeline from the anchor line, making it impossible to fall off the roof (the worker is protected by travel restraint, which is safer than fall arrest and does not require a rescue plan). A six‑foot lifeline (lanyard) connecting a worker to the anchor line between Eveooks creates a safe working zone that is up to approximately 12 feet wide along the entire length of the anchor line. Roof work can be organized to sequentially move the 12‑foot working zone as many times as needed to protect access to the entire roof surface. Shown in the images above are adjustable lifelines that can span from one to thirty feet, allowing a safe working zone that is up to approximately 60 feet wide at any point along the entire length of the anchor line.

11. Workers tend to want as wide a working zone as possible (as illustrated in Figure 1). Unfortunately, with classic fall protection, this increases the probability of sustaining a fall off the roof and increases the potential magnitude of a swing fall. Ballantyne Gear has developed robust Eveook System layouts, procedures, and training to minimize the number of required relocations of the Eveook anchor line and the need to remove and reattach the worker’s lifeline every time they move to a new work zone, which has greatly reduced the possibility of falls, including swing falls, while increasing the safety and efficiency of the system.

12. Significant work has gone into addressing the challenges faced in evolving to the Current Eveook System. Ballantyne Gear and I have conducted extensive and expensive research and development, computer modelling, and confirmation testing to prove the viability and safety of the new Eveook System, including:

a. Travel restraint on sloped roofs, such that a fall cannot occur, using a synthetic horizontal anchor‑line rope, which has proven to be very reliable. These synthetic ropes are far more functional than less‑expensive but more conventional straps, since they can support a fall arrester, whereas the straps only support free‑sliding connectors, such as a carabiner.

b. The stretch (and sag) properties of the Eveook anchor line and the user’s adjustable lifeline have been improved through a selection of stronger and stiffer synthetic ropes that exhibit much less stretch and behave in a more linear fashion, reducing fall‑clearance requirements and creating a system that is strong enough to protect up to eight users on one system (generally four users on each side of the primary ridge).

c. Finding a fall arrester that also works as a rope grab and includes a built‑in 1,300‑pound energy absorber, improving safety and efficiency. This fall arrester can be used for fall arrest, fall restraint, and positioning. Because of the 1,300‑pound energy absorption, it reduces the fall‑clearance requirement compared to the clearance requirement of the more standard 600‑pound energy absorber.

d. Developing a more reliable understanding and prediction of the variability of the frictional forces and development of suitable friction factors to absorb some of the energy of a fall. This understanding was a result of the hundreds of friction tests that we made with multiple rope sizes and materials, multiple roofing materials, and multiple roof pitches.

e. Learning how the deflection of the anchor line over “significant ridges,” such as might be provided by dormers, a roof peak, or other transverse features, allows them to act as pseudo‑intermediate supports to the main anchor line, reducing the sags and clearance requirements.

f. Development of a new body for the Eveook anchors that is stiffer and stronger than the original.

g. Determining, through testing, the forces that an eave anchor must exert on a roof before the roof might sustain damage, and confirming that these forces are well beyond what would occur in a typical fall. We have also proven that both the eave anchor and the roof have a very robust factor of safety and that a roof can absorb significant energy, if required, to resist some kind of major abuse of the Eveook System.

h. Development of a highly complex computer model that goes well beyond the industry norms of horizontal lifeline analysis to predict the behavior of the anchor line in the Current Eveook System. It incorporates the research and development listed in a‑g above to confirm that the Current Eveook System safely protects workers on roofs and other applicable at‑height locations.

While I was engaged in the engineering work listed above, Ballantyne Gear researched and developed practical options for installing the entire Eveook System while maintaining three points of contact with a portable ladder. The following YouTube video link confirms how the installer is protected from falls since the fall‑protection system can be installed before anyone sets foot on the roof and how the person installing the second Eveook, from a ladder, uses fall protection provided by the first Eveook. On some low‑height roofs, the system can be completely installed without anyone being on a ladder without fall protection. https://youtu.be/rqm-lTlfL-0?si=ekz0pBZoJkk2aKT3

As a result of testing at an independent ISO 17025 lab, onsite testing, and the work described above, on December 22, 2020, I certified the Eveook System and method of installing and using it meets the ANSI Z359.6‑2016 Standard in the United States and the CSA Z259.16‑15 in Canada as an engineered fall‑protection system for workers on sloped roofs. This required that all the individual parts of the system be tested to meet their individual requirements and that the complete system be tested to meet the requirements of the ANSI Z359.6 and the CSA Z259.16 Standards. Furthermore, I certified that the Eveook System and Method meets OSHA 1910.140 and 1926.501 Standards.

13. To the best of my knowledge, the Eveook System I have certified is the only fall‑protection system for residential‑style sloped roofs in the United States or Canada that has been engineered to the standards listed in the above paragraph.

Respectfully,

Greg Small

Date: April 28, 2025

I’m Jeff Horwitz, writing a letter of recommendation for the Ballantyne Gear Eveook Fall Protection System.

1- I received a Bachelor’s degree in International Affairs from Seton Hall University in 1980 and a Juris Doctorate degree from the University of Pittsburgh in 1987. Additionally, I earned my Master’s degree in Homeland Security from American Military University in 2008.

2- I am currently the CEO of SAFE Project, which is a national nonprofit committed to contributing to the addiction and overdose crisis facing our country. In this role, I oversee the day‑to‑day administrative and operational functions of SAFE Project, as well as the financial management of the organization. Additionally, I am responsible for working with outside nonprofit and for‑profit organizations to infuse a focus upon safety and collaboration into all our work. In addition to this work, I serve on the Board of St. Joseph University’s Center for Addiction and Recovery Education (CARE) and Heartshine, a resilience and trauma support community program in Harrisburg, Pennsylvania.

3- Prior to arriving at SAFE Project, I served 28 years in the United States Navy. I retired as a Captain in 2014. In addition to his final assignment as the General Counsel of the White House Military Office, I served in multiple assignments including Command Judge Advocate on board the USS Harry S. Truman (CVN 75); Staff Judge Advocate, COMNAVAIRFOR; Counsel for the Commander, U.S. Naval Forces in Northern Europe and the United Kingdom; and Director of the Navy’s Legislative Program for nearly nine years.

4- There are nearly 20,000 serious injuries from construction falls per year in the U.S. and 300 accidental work deaths. In addition to the physical toll of these injuries, the circumstances carry a significant emotional toll too. Two clear indicators of this emotional toll are suicides and the misuse of substances as a coping mechanism to address emotional triggers. Annually, there are approximately 6,000 construction worker suicides in the U.S. per year, roughly 75 percent greater than the norm. In regard to substance use, it is important to note that construction workers are seven times more likely to undergo an overdose than any other member of the workforce. Although we cannot directly correlate all these outcomes to construction falls, it is evident that they are outcomes from the stresses related to the construction workforce – which includes the stress relating to the fear of injury or death on the job – including injuries and death that could result from a fall while working on a roof.

5- I first learned about Ballantyne Gear’s Eveook Fall Protection System (“Eveook System”) at the 2025 Annual International Builders Show and the National Association of Home Builders (NAHB) Conference. For many years, SAFE Project has been an invited guest of both the NAHB and the Job Safety Institute, to work directly with the construction workforce on the growing concerns relating to the safety of the construction workforce. I became interested in the Eveook System as a way to improve construction worker safety, and thereby reduce stress for these workers to hopefully reduce the mental‑health impacts described above.

6- I am aware that there are other fall‑protection systems on the market but believe many of these still have issues and there is a need for improved safety for construction workers.

Respectfully

Jeff Horwitz

Date: 4/29/2025

I'm Ron Kinville, writing a letter of recommendation for the Ballantyne Gear Eveook Fall Protection System.

1. I received an Ed.D. from Aspen University in 2018. I received an MS in Safety, Security and Emergency Management from Eastern Kentucky University ("EKU") in 2010. I also received a BS degree in Construction Management from Brigham Young University- Idaho ("BYU-I") in 2008. I am an authorized OSHA Outreach Instructor in both General Industry and Construction Safety. I am certified by the Board of Certified Safety Professionals ("BCSP") as a Certified Safety Professional ("CSP").

2. I am currently a Construction Management Professor at Brigham Young University-Idaho ("BYU-I") in the Department of Design and Construction Management. I have been a professor at BYU-Idaho since 2008 and have taught Construction Safety for 46 semesters. I have also been employed as a Safety Manager and Safety Trainer with NPL Construction Co. I am a licensed general contractor in the state of Idaho, and the owner of Kinville Enterprises, LLC. (Est. 2006).

3.Prior to my employment as a professional educator, I worked in the roof truss industry for 27 years, including managing and owning truss manufacturing facilities.

4. Having experience in construction, including construction safety, I am familiar with safety concerns related to workers working on elevated structures, including sloped roof surfaces. I know that according to the Bureau of Labor Statistics ("BLS") and the Occupational Safety and Health Administration ("OSHA"), falls are the leading cause of death in the construction industry. I am also familiar with the various systems and methods commercially available to help protect workers from falls, including non- penetrating systems that do not cause damage to the roof or building as part of installation. One such non-penetrating, sloped roof system is Ballantyne Gear's Eveook Fall Protection System commercially available through Ballantyne Gear at https://www.ballantynegear.com/collections/product-list ("Eveook System").

5. I first learned about the Eveook System at the National Association of Homebuilders (NAHB) International Builders Show (IBS) in 2024, where I saw demonstrations and videos of the system.

6.I was particularly impressed by two primary benefits of the Eveook System over other non-penetrating, sloped roof fall protection systems of which I am aware.

7. One of these benefits is the ability to install the Eveook System from positions on the ground and/or on a ladder. There is no need for an installer to physically climb onto the sloped roof, unprotected from a fall, to install the Eveook System. There are other systems that require an installer to be on the roof, and particularly at or near the roof peak to connect components of the system together as part of installation, making the installer vulnerable to a fall. The Eveook System uses a line thrower to position a single anchor line over the sloped roof to connect to two eave anchors together without requiring the installer to physically climb on the roof unprotected.

8.There has been a need in the industry for many years for a non-penetrating fall protection system for use on sloped roofs that allows installation without the user having to climb on the roof. Prior to the introduction of the Eveook System in 2018, I am not aware of any non-penetrating fall protection system for use on sloped roofs that could be installed without the user having to climb on the roof climbing on the roof was standard for installation of such systems.

9.A second benefit of the Eveook System is providing two points of connection that both allow for sliding and anchoring. This is illustrated in the blue and yellow circles added to the drawing below, which is reproduced from the Technical Manual for the Eveook System (available under the Technical Tab at https://www.ballantynegear.com).

10. First, the user's personal lanyard/harness is connected to the lifeline using a rope grab or Goblin. This connection point is shown in the blue circle. This type of connection to the lifeline has been used in other systems prior to the Eveook System.

11. Second, the user's lifeline is connected to the anchor line, using a rope grab of Goblin. This connection, which is shown in the yellow circle, is new and unique in the Eveook System.

12. The use of a rope grab or Goblin for these connections allows each connecting device to freely slide along the line to which it is connected (the anchor line or the lifeline) in one direction but to not allow free sliding in the opposite direction unless the rope grab or Goblin is actuated by the user to allow sliding in that direction. By not allowing free sliding in the opposite direction, the rope grab or Goblin allows the user to anchor to a selected position on both the anchor line and the lifeline. Other systems that I am aware of may allow similar sliding and anchoring on the lifeline (the blue circle), but not on the anchor line (the yellow circle) and on the lifeline (the blue circle).

13. Alternatively, from paragraph 10, the user's personal lanyard/harness can be connected to the lifeline using a fall arrester that will move freely up and down the line, when hands free fall protection is required, such as when tearing off shingles from a roof.

14. There has been a need in the industry for many years for a non-penetrating fall protection system for use on sloped roofs that allows a user to safely access greater areas of the roof. Prior to the introduction of the Eveook System in 2018, I am not aware of any non-penetrating fall protection system for use on sloped roofs that included two connection points that both allow for sliding and anchoring, one being for connecting the user to the lifeline and the other being for connecting the lifeline to the anchor line. For other systems, the connection of the lifeline to the anchor line is either (1) freely sliding in both directions (no anchor point at all), which presents a risk of falling off the roof completely) or (2) is a fixed anchor point (usually at the roof peak), which limits the user's ability to safely access all points of the roof needing work or requires the user to lengthen the distance between the lifeline connection and the anchor line to reach those areas, which can also result in a fall.

15. When I first saw the Eveook System, I was skeptical of the practicality of using such a bulky and heavy metal support (in the C-shaped eave anchors) connected together with a single anchor line. Only after I hefted the device and realized how easy it was to lift into position at the eaves using the single anchor line and a progress capture pulley or ratchet all from a position on the ground or a ladder was I convinced that this is truly a unique and practical method for saving lives from falls in construction.

Respectfully.

Dr. Ron Kinville Ed.D, CSP

Date: 23-APRIL-2025

I'm Calvin Beyer, writing a letter of recommendation for the Ballantyne Gear Eveook Fall Protection System.

1. I am submitting this declaration independent of the organization I am currently employed by for practical reasons. I am voluntarily agreeing to submit this declaration in support of the patent submission based on 30 years of relevant experience in construction insurance and risk management and safety consulting. Falls from heights are one of the leading causes of serious disabling and fatal occupational injuries in the US construction industry. I am receiving no compensation or other consideration for submitting this declaration. I am doing so because the product being evaluated bridges a known gap in worker safety and is an innovative solution that can easily remedy unprotected workers and be readily implemented on a construction site.

2. I received a BA degree from the University of Wisconsin at Madison in 1986 and a Master of Public Administration from the University of Kansas in 1988. I received a Certified Wellness Practitioner (CWP) certification from the National Wellness Institute (now National Wellness Alliance) in June 2020. I also earned a Safety Certified Transportation Project Professional Certification from the American Road and Transportation Builders Association (ARTBA) in 2020.

3. My professional career began in earnest while in graduate school where I worked for both the Johnson County (KS) County Government in the Offices of Management & Budget and as resident assistant for the University of Kansas Housing Department. I served a one-year externship with the City of Lake Forest, IL, as Administrative Assistant to the Director of Parks, Forestry and Public Works. I served as Safety Officer and Scribe for the Safety Committee in this role. Subsequently, I worked in the insurance industry in various capacities, including:

⚫ 1988-1992 - Gallagher Bassett Services as Manager, Governmental Services

and the Institute of Liability Management. I specialized in providing risk management and safety consulting services to risk retention groups across the country.

-1992-1996 Cities & Villages Mutual Insurance Company (CVMIC) in

Brookfield, WI as a Liability and Workers Compensation Specialist.

⚫ 1996-2023 Zurich North America Insurance as Risk Engineering Manager and several additional business executive roles in the Construction Business Unit.

⚫ 2003-2010 - Arch Insurance Group as Vice President of Risk Control Services for the Construction, National Accounts, and Alternative Risk business units. • 2010-2013 I returned to Zurich North America Insurance as First Vice President of the Manufacturing Business Unit to build a specialized practice to rival the construction business unit.

⚫ 2013-2014 - Murray Risk Management in Lancaster, PA, to develop a large, complex and alternative risk account capability. I left to join Lakeside Industries which allowed me to launch a national campaign focused on workplace mental health, substance misuse and suicide prevention that ultimately morphed in 2016 into the Construction Industry Alliance for Suicide Prevention (www.preventconstructionsuicide.com) that organized as a nonprofit in 2018. From August 2014 to March 2020, I served as Director of Risk Management and oversaw safety and claims management functions for Lakeside Industries in Issaquah, WA. This organization had approximately 650-700 employees in 15 divisions with 20 aggregate mining and asphalt production facilities. I oversaw a significant upgrade in personal fall protection systems to protect plant production and maintenance workers working from elevated work platforms and systems, and while performing confined space entry operations. This was one of my most important accomplishments in my tenure as risk manager.

I am currently the Senior Director of SAFE Workplaces at national nonprofit SAFE Project, which is an organization seeking to address mental health and substance use. SAFE stands for Stop the Addiction fatality Epidemic. I have been with SAFE Project since March 15, 2024. Prior to this position, I worked as an independent consultant from September 2023 to March 2024 which included limited work as a contractor for SAFE Project and my then former employee Holmes Murphy & Associates (HMA) which is based Waukee, IA. For HMA, I served in a national role as Vice President for Workforce Risk & Worker Wellbeing from March 2020. In 2023 and again in 2024 I declined to move to Des Moines or Kansas City to continue my career with HMA. I negotiated an exit strategy to perform independent consulting while I evaluated nonprofits to focus my final years of my career on addressing addiction treatment and recovery and overdose prevention in workplaces. As a member of the Executive Committee of the National Action Alliance for Suicide Prevention I worked to have the intersection between substance use and suicide included in the 2024 National Strategy for Suicide Prevention. When the final draft was released, I made a decision that I was going to seek a nonprofit to closed out my final work years pursuing strategies and tactics to address this intersection. This is how I came to join SAFE Project. I had collaborated with SAFE Project for over two years before I started contracting with them on project work.

4. I am well known in the US construction industry as a human capital risk management specialist. I am a frequent speaker at safety, risk/insurance management, and construction and other industry national, regional and local conferences. I have authored or co-authored over 150 articles in various construction industry publications. I have received numerous awards and recognitions from various organizations for my work with workplace mental health, substance misuse, suicide prevention, and opioid risk management.

Notable among these are:

• United Suicide Survivors International (USSI). Inaugural recipient of Lifetime Achievement Award for Mental Health promotion, Suicide Prevention and Addiction Recovery at Work. February 29, 2024.

• National Association of Home Builders (NAHB). Inaugural recipient of Safety Award for Excellence (SAFE) as 2021 Industry Advocate for Mental Health. January 21, 2022.

⚫ Humanitarian Award by Lakeside Industries for lifesaving work on mental health and suicide prevention. March 2019.

Chairman's Award by the Construction Financial Management Association. June 25, 2018. One of 10 leaders selected since 2011 from over 10,000 members.

• Top 25 Newsmaker for 2016 by Engineering News-Record. (New York, NY). April 29, 2017. One of 25 leaders in the global construction industry recognized by the editors of ENR for addressing suicide prevention in the construction industry. Award began in 1964 with only 1,500 designated global recipients. • Danny Parrish Outstanding Leadership Award by the Construction Financial Management Association. June 29, 2016. The top leadership award with only 15 leaders selected since 2021 from over 9,000 members.

• President's Leadership Award, Argosy University. March, 2010.

5. In 2010 I was an inaugural appointee to the then Workplace Task Force for the newly formed national Action Alliance for Suicide Prevention. I was the first non-clinician appointed to this role. I started a construction subcommittee by 2012. I served as Co- Chair from 2013 to 2017. I was appointed to the Executive Committee for this public- private partnership with over 250 partner organizations. I also serve on the Lived Experience Advisory Committee of the Suicide Prevention Resource Center. I termed-out as an advisor to the Expert Advisory Group of the American Psychiatric Association's Center for Workplace Mental Health. I serve as an uncompensated advisor for several firms I elect to collaborate with because of mutual alignment with values and services. I spoke at a Men's Health Conference sponsored by the White House in January 2016. I also provided post-pandemic virtual testimony to a committee of the Food and Drug Administration (FDA) in support of testing products to detect the genetic predisposition for opioid use disorder.

6. I understand that there are around 20,000 serious injuries from construction falls per year in the US and 300 accidental work deaths. I also understand that suicide is a frequently overlooked cause of death among construction workers. There are around 6,000 construction worker suicides in the US per year, roughly 75% greater than the norm. This means between 5-6 times more workers die by suicide annually than from all occupational injuries combined (based on Bureau of Labor Statistics annual Census of Fatal Occupational Injuries).The rate of suicide in the construction industry is 56 deaths per 100,000 workers among males and 10.4 among women vs. 32 and 8 for males and females in all industries. The overdose rate for construction is the highest among 19 major industry groupings analyzed in a CDC Vital Statistics Report from August 2023 at 130.9 per 100,000 workers vs. an average of 41 for all 19 industry groupings.

7. The intersection between substance use and suicide is a special areas of passion and focus for me. I have personal and family lived experience with prescription opioid use, misuse, and abuse dating back to my teenage years after multiple surgeries to repair a damaged knee joint.

8. Data shows that a person with alcohol use disorder is 8 times more likely to die by suicide and that a person who uses multiple substances is 17 times more likely to die by suicide. The CDC has indicated that stress, anxiety, depression, and musculoskeletal injuries (chronic pain and opioid prescriptions) are major contributing factors for the substance use, suicides and overdoses among construction workers. These workers frequently have to deal with the stress of working away from home, the stress of deadlines, and the stress of working with a constant fear of injury or death on the job - including injuries and death that could result from a fall while working on a roof.

9. I first learned about Ballantyne Gear's Eveook Fall Protection System ("Eveook System") in March 2024 when the company received the Safety Award for Excellence (SAFE) by the National Association of Home Builders (NAHB) and Builders Mutual. As a prior SAFE Award recipient, I always pay attention to the annual awards process. I became interested in the Eveook System as a way to improve construction worker safety, especially for reducing AND actually preventing falls from elevation while working on or preparing to work on sloped/pitched (high angle) roofing systems.

10. For many years, fall protection systems for pitched/sloped roofs was insufficient and cumbersome or installation of prior systems could damage existing roofing substrates leading to water infiltration. These complications and "side effects" lead some companies to forego fall protection thereby sacrificing worker safety over concerns of risk management and quality. This contributed to an unchecked culture of risk-taking jeopardized worker safety. There are studies that point to workers who feel safe actually are more productive and feel empowered to focus on concentrate on quality, which reduces the risk of construction defects and rework. Of course, it is positive that an ancillary benefit of an effective fall prevention system is reduced stress for these workers to hopefully reduce drug-use, suicide and overdose risk among construction workers.

11. I am aware that there are other fall protection systems on the market, but believe many of these still have issues and there is a need for improved safety for construction workers. For the past five to six years, I have almost exclusively focused on worker wellbeing as my professional scope of services. However, in my 35 years of risk management and safety experience, I have been aware of the dangers of workers not being protected by fall protection. As an insurance risk and safety consultant and as director of risk management I spent a significant amount of my time helping construction companies:

⚫ understand the need for fall protection

⚫ evaluate alternative fall protection (restraint and prevention) systems and equipment,

⚫ ensure workers were properly trained how to properly wear, inspect and

care for this equipment

⚫ monitor and document proper usage and inspection and replacement of fall

restraint and protection systems and equipment.

12. Roofing fall protection has been an area in need of innovative solutions. When the President of Ballantyne Gear, Mr. Flent Ballantyne, shared with me that he had been working to develop, engineer, design, and manufacture the Eveook System since at least 2010, I congratulated him for his sacrifice of solving a problem that had been overlooked for too long. When workers are subjected to using safety equipment that is not customizable to their needs, safety shortcuts are taken in the name of productivity and quality. Sadly, it remains frustrating that it has taken this long for some industry professionals to see value in a custom, engineering fall protection system specifically designed for roofing structures and systems.

13. SAFE Project had the privilege of exhibiting at the 2025 NAHB International Builders Show in Las Vegas in February 2025. SAFE Project's booth space was directly adjacent to the exhibit for Ballantyne Gear. I saw the reaction by construction professionals who visited their booth and had an opportunity to learn about the Eveook system. Some of the reactions that stood out for me as a risk management and safety professional included the following:

⚫ The system is intended to support the fall protection anchorage needs for a typical crew up to a size of 8 workers. A major exposure of traditional roofing systems for sloped or pitched roofs is swing falls. The Eveook system protects workers prepare to access the roof such that the installation team (or individual) will be protected as they complete the installation process.

• The ease of installation was something most professionals were not expecting. Visitors to the booth were pleasantly surprised that installation could take less than 15 minutes and provide multiple points for anchorage to workers tying off with lanyard fall protection devices.

⚫ I repeatedly heard how people appreciated how the Eveook system does not require nails, screws or any other fasteners to penetrate the roofing substrate systems. This reduces the risk of roofing damage claims or implied or expressed warranty claims. This is a secondary risk management benefit compared to other types of fall protection systems I have seen used in the past.

Respectfully,

Calvin (Cal) Beyer

Date:

· April 19, 2025

Sign up for our newsletter

For desktop users scan and mobile users press and hold QR code to stay in touch and receive our weekly newsletters.

Be sure to check and click on the verification email.